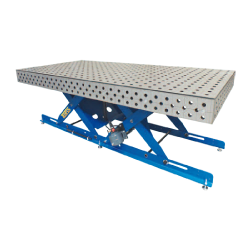

| Type / Item No. | Work Area – in mm | Table Top Thickness – in mm (h) | Table Height – in mm | Max. Load – in kg | Net Weight – in kg |

|---|---|---|---|---|---|

| SSTW 80/35-200M | 2350 x 1150 | 35 | 800 | 2000 | 588 |

3D-Welding Table Systems: SSTW-Fix Series (M)

3D-Welding Table Systems of the SST-Fix Series are ideal workplaces for efficiently welding and adhesive bonding structures such as railings, racks, appliances, etc.

With the help of our extensive assortment of clamping devices (see section „3D-Welding Table Accessories“) these table systems themselves are usable as flexibly equipped appliances and thus allow for high-quality manufacturing of small and medium volume products.

Work tables of 25 to 35 mm thickness, equipped with a 28 mm dia. hole grid, are used for this purpose in 3D-Welding table systems. In addition, the table has 100 x 100 mm grid markings for easy alignment of work pieces or fixtures. The hole grid allows to use a variety of clamping elements and fixation aids. Due to the special comprehensive bolted joint design of the clamping plate the work area can be exchanged at low cost if required or in case of excessive wear. The table system is therefore especially long-living.

Due to the modular design the user can attach various kinds of accessory equipment such as exhaust hoods or storage shelves (see section „3D-Welding Table Accessories“).

Features of the TEMPUS® SST fix Series

- extremely rugged solid steel design

- comprehensive bolted joint design

- secure and stable by up to 833 kg net weight and levelling feet

- table top of 25 to 35 mm thickness with 28 mm dia. hole grid

- 100 x 100 mm line grid efficient clamping and fixing

- variety of table top materials (aluminium, stainless steel)

- surface KTL coated RAL 9005 black (except table top)